Supply Chain Management

Supply Chain Management

Significance & Commitment

Supply chain management plays an important role in moving the Company forward as efficient management does not only reduce the risks of business interruption but also enhances the operational efficiency. Promoting ESG principles across the supply chain is thus one of the Company’s missions.

Management Approach

The Sustainable Supply Chain Policy was announced as a commitment to creating long-termvalue for all stakeholders. Moreover, 5-year strategic plan (2018-2022) was also developed asroadmap. The Supplier Code of Conduct has been published as a guideline for all existing andpotential suppliers to ensure that they operate the business in adherence to environmental, socialand governance (ESG) principles.

At present, the Supplier ESG Due Diligence is under standardization. When this process is fully implemented, critical suppliers will be identified and carried out a preliminary ESG risk assessment. In the case where a critical supplier is identified as high ESG risk, the supplier shall prepare preventive or corrective measures with a comprehensive audit plan. The Company then conducts an audit as specified in the plan once a year.

Furthermore, the spending analysis has been performed in each country to identify areas for cost reduction as well as process improvement opportunities. The Company also supports local procurement by seeking to engage goods and services with local suppliers in the areas of business operations. However, the data collection system for local procurement is under standardization for all business units.

Supplier Risk Assessment

Banpu Power, the Company’s subsidiary, conducts quarterly supplier risk assessments as part of its oversight responsibilities for the Risk Management Committee and Audit Committee. In 2024, key high-priority risks include:

• Inability of suppliers to deliver coal or natural gas in accordance with the required price, quality, and delivery timelines

• Machinery part shortages due to procurement delays

• Operation and maintenance (O&M) contractors failing to meet plant reliability, safety, and quality expectations

Supply Chain Risk

Risk Mitigation Measure

Inability of suppliers to deliver coal or natural gas in accordance with required price, quality, and delivery timelines

· Use of the IRIS application for real-time monitoring

· Establishment of long-term sales contracts or forward purchase agreements

· Expansion of coal storage capacity to buffer against supply disruptions· Use of the IRIS application for real-time monitoring

Machinery part shortage due to procurement delays

· Maintain inventory of critical spare parts at power plant sites

· Conduct site visits to supplier facilities for proactive issue resolution and timeline tracking

Operation & maintenance (O&M) contractor failing to meet plant reliability, safety, and quality expectations

· Provide targeted training programs to improve contractor competency

· Implement a Safety and Occupational Health Management System (OHSMS) to ensure performance alignment with operational standards

Customer Relationship Management

The Company takes a tailored approach to customer relations to ensure alignment with customer needs and expectations across each business context. Beyond regular satisfaction surveys, we engage through various channels–ranging from in-depth interviews and on-site visits to knowledge-sharing sessions, quarterly performance updates, and open house events.

Business

Example of Customer Relationship Approaches

Mining

· Customer satisfaction survey

· Regular customer site visit

· Knowledge-sharing session

· Quarterly performance report

· Open house event

Thermal power

· Customer satisfaction survey

· Regular customer site visit

· Technical support

Solar rooftop

· Customer satisfaction survey

· Technical support

· Returns on investment evaluation report

· 24-hour customer service

Energy trading

· Customer satisfaction survey

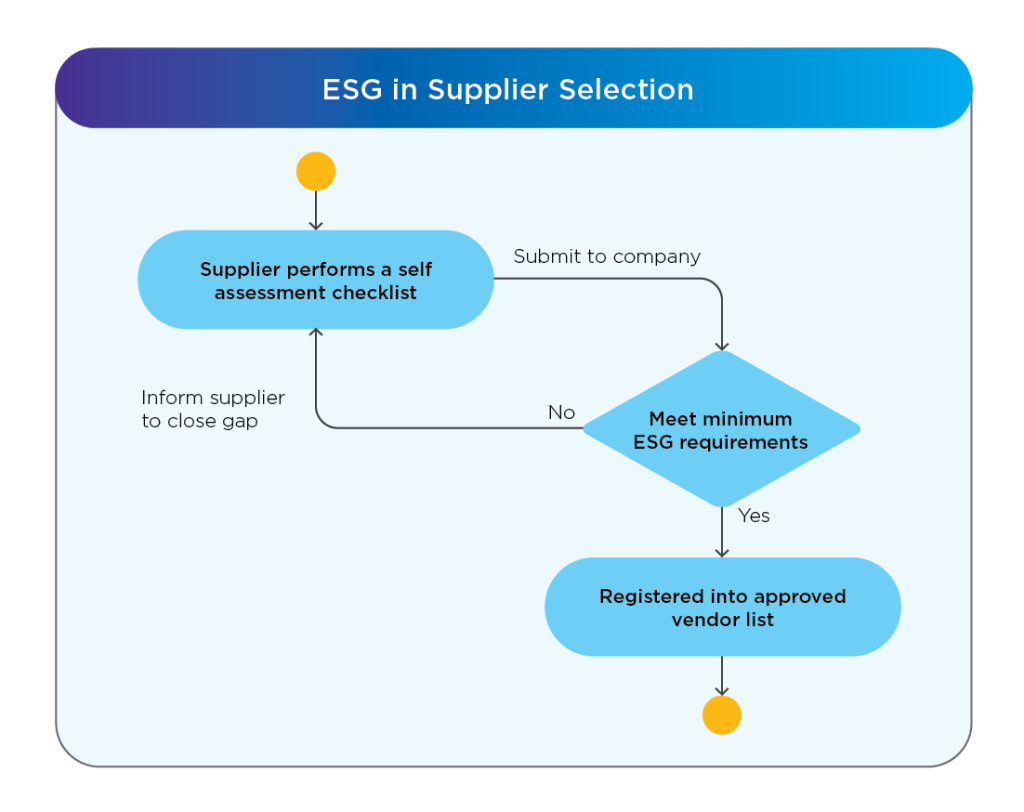

ESG in supplier selection

The Company has refined the supplier selection process by integrating best practices from subsidiaries and industry peers to develop a “pre-qualification checklist”. The criteria include social aspects such as health & safety and community impact, environmental aspects such as waste management, and governance aspects such as business ethics. While a self-assessment questionnaire serves as a tool for suppliers to evaluate their ESG performance, with scores evaluated based on evidence-supported responses. The results influence the vendor screening and selection process, ensuring qualified suppliers are selected.

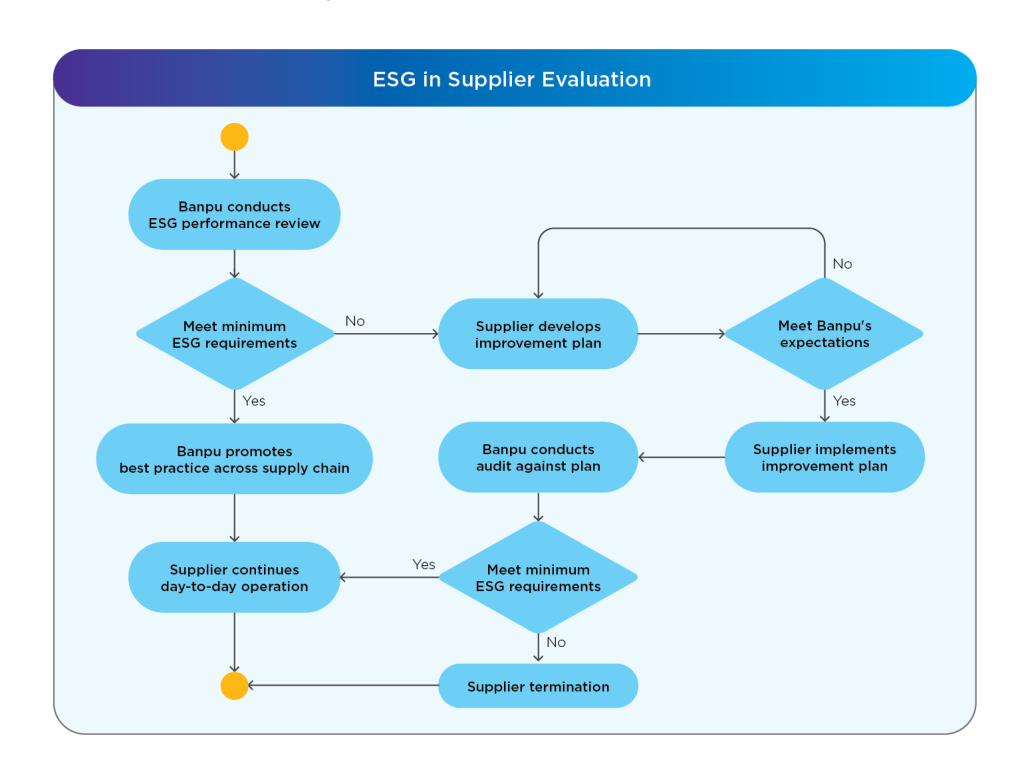

ESG in supplier evaluation

Simultaneously, ESG in supplier evaluation is designed to assess supplier performance during and after the service delivery. The evaluation are conducted by the Company and, where necessary, the third-party auditors, using a combination of desk-based and onsite assessments. This process is crucial for identifying actual or potential negative ESG impacts, ensuring compliance with ESG standards, and fostering continuous improvements in supplier practices. This is essential for the Company to identify, monitor, and address impacts, including the potential termination of suppliers that fail to meet minimum ESG requirements.

In 2024, BanpuNext, the Company’s subsidiary in Thailand, initiated implementing the ESG in supplier evaluation and actively enhancing effectiveness while simultaneously developing a robust internal implementation standard.

Year in Review

In 2024, the Company established the Supply Chain Committee as the formal governance body responsible for overseeing the integration of ESG into supplier management practices. The Supplier Code of Conduct was revised to clearly define ethical, social, and environmental expectations for all suppliers. This updated framework goes beyond regulatory requirements, aligning with international sustainable procurement best practices. Moreover, the Company continues conducting a comprehensive supplier segmentation analysis. This year, we have successfully implemented this practice within our business operations in China..