Decarbonization & Climate Resilience Projects

Energy Reduction from Coal Handling in Indonesia

In accommodating customer demand and blending various coal types, the utilization of Low CV coal sourced from third parties has been favored. However, this type of coal tends to cause blockages within chutes during the rainy season, disrupting the seamless transfer of coal between conveyors. Such blockages not only prolong cleanup efforts but also interrupt loading processes. Traditionally, chute blockages were managed using labor-intensive techniques like high-pressure water spraying or manual removal, which were constrained by limited staff availability.<br><br>In response to the operational inefficiencies and environmental concerns linked to excessive water usage, Bontang Coal Terminal (BoCT) in Indonesia introduced an innovative solution in March 2022: “the installation of air cannons in transfer chutes”. These cannons autonomously release periodic air blasts to clear material buildup. Since implementing this system, remarkable improvements have been observed:<br>• 80% reduction in delays and cleanup times due to chute blockages<br>• 5% increase in gross loading rate<br>• Annual reduction in energy consumption by approximately 538 MWh, leading to a decrease in GHG emissions of around 125 tCO2e per year.<br><br>These outcomes underscore the effectiveness of the air cannon system in enhancing operational efficiency while mitigating environmental impacts.

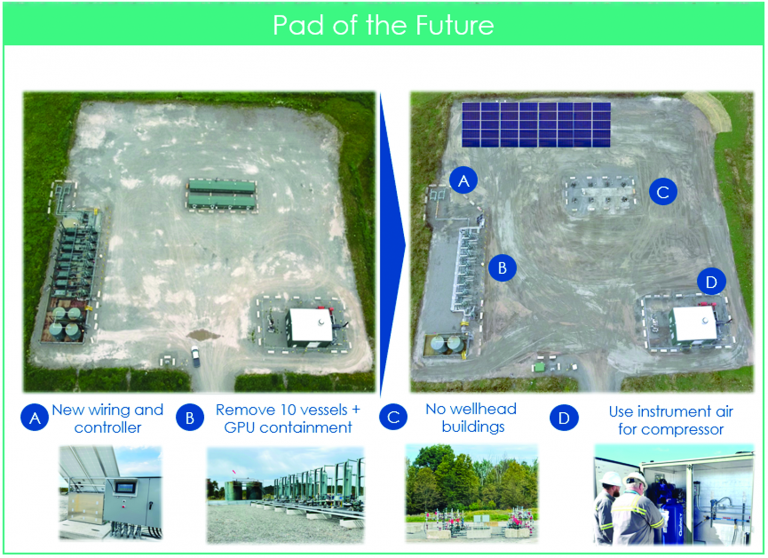

View MorePad of the Future

BKV, a subsidiary in the US, has taken a groundbreaking step towards decarbonization with the Pad of the Future program. This flagship initiative aims to reduce emissions within NEPA and Barnett operations by integrating operational improvements and modern technology. Launched in 2021, the program is a testament to BKV’s commitment to enhancing efficiency and minimizing carbon footprint through 4 strategic pillars:<br>• Pneumatic conversion: Convert natural gas-powered pneumatic controllers to compressed air on existing electrified pads.<br><br>• Electrification: Where feasible, electrifying pads to supplant use of natural gas in processing units and adding solar power to support pneumatic conversions from natural gas to air.<br><br>• Asset consolidation: Streamline and modernize existing pad facilities to reduce emissions caused by aging assets.<br><br>• Liquid consolidation and vapor capture: Minimize onsite storage of condensate and oil by transporting liquids rich in natural gas to centralized facilities.<br><br>With an estimated investment of 35 to 40 million USD, the program is set to impact over 6,000 of BKV’s existing wells (more than 8,000 pneumatic devices and 2,000 pneumatic pumps) by the end of 2025. To date, these efforts have led to an aggregate reduction of 515,000 tCO2e in 2023 and anticipated reduction of approximately 770,000 tCO2e by the end of 2025.

View MoreGREENCODE Digital Platform

ITM, a subsidiary in Indonesia, faced with the challenge of carbon stock data gathering from the reclamation process due to manual data collection and no standard reference. This inefficiency delayed data collection and validation.<br><br>To pursue this challenge, ITM initiated the GREENCODE project, which is a digital platform and dashboard designed to ensure the validity and visibility of carbon stock data. The project was rolled out at Embalut and Jorong mine.<br><br>The introduction of GREENCODE has significantly improved the efficiency and effectiveness of reclamation monitoring. It has also enhanced decarbonization knowledge of team members. Economically, the project has delivered tangible benefits by reducing lead time to update carbon stock data of USD 36,746 annually. The Company also potentially minimizes future carbon tax and ensures reclamation compliance.

View MoreReducing Emissions through Gas-to-Energy Initiative

Mandalong, an underground coal mine in Australia, is characterized by its complex and large-scale emissions profile. These emissions mainly come from three ventilation fans that expel air from the mine. This air carries gases released from the coal extraction process and older, sealed areas. To manage inseam gas content, the site uses a gas drainage system, which plays a crucial role in maintaining mine safety and production efficiency.

View MoreFlue Gas Heat Recovery Project at Zouping

With carbon emissions allowances for coal-fired power plants becoming increasingly stringent, reducing coal consumption while maintaining stable operational performance has become a crucial priority.

View MoreEnergy Management

Given the diversity of operations, the Company adopts tailored energy conservation strategies across each business sector to maximize efficiency and system reliability.

View MoreList of Reduction of GHG and Energy Consumption Initiatives

To support our Net Zero journey, Banpu has implemented several GHG emissions reduction initiatives across our business operations. For each initiative, emissions reductions are quantified by comparing actual performance against a baseline scenario, reflecting conditions prior to the implementation of these initiatives.

View MoreClimate Scenario Analysis Aligned with TCFD Recommendations

The Task Force on Climate-related Financial Disclosures (TCFD) framework recommends that organizations disclose the actual and potential impacts of climate-related risks and opportunities on their business strategy and financial planning, within a defined strategic boundary. In alignment with these recommendations, Banpu has conducted a comprehensive assessment of climate-related risks and opportunities using 4 climate scenarios:

View MoreOpportunity under Emission Trading Scheme (ETS) in China

Launched in 2021, China's Emission Trading Scheme (ETS) marks a pivotal move in cutting the nation's carbon emissions. The scheme distributes emission allowances based on the power plants' generation output, with benchmark criteria that vary by fuel type and technology. It also enables companies to trade these allowances, granting them the right to emit a specific amount of carbon dioxide.

View MoreBarnett Zero, The First Carbon Capture and Sequestration (CCS) project of Banpu

The Barnett Zero Project is a Carbon Capture and Sequestration (CCS) initiative led by BKV, a subsidiary in the U.S., and EnLink Midstream. It is one of the first commercial CCS projects in the U.S., aiming to reduce CO2 emissions from natural gas production in the Barnett Shale region of Texas.

View More